18151596636

18151596636

18151596636

18151596636

SERIES

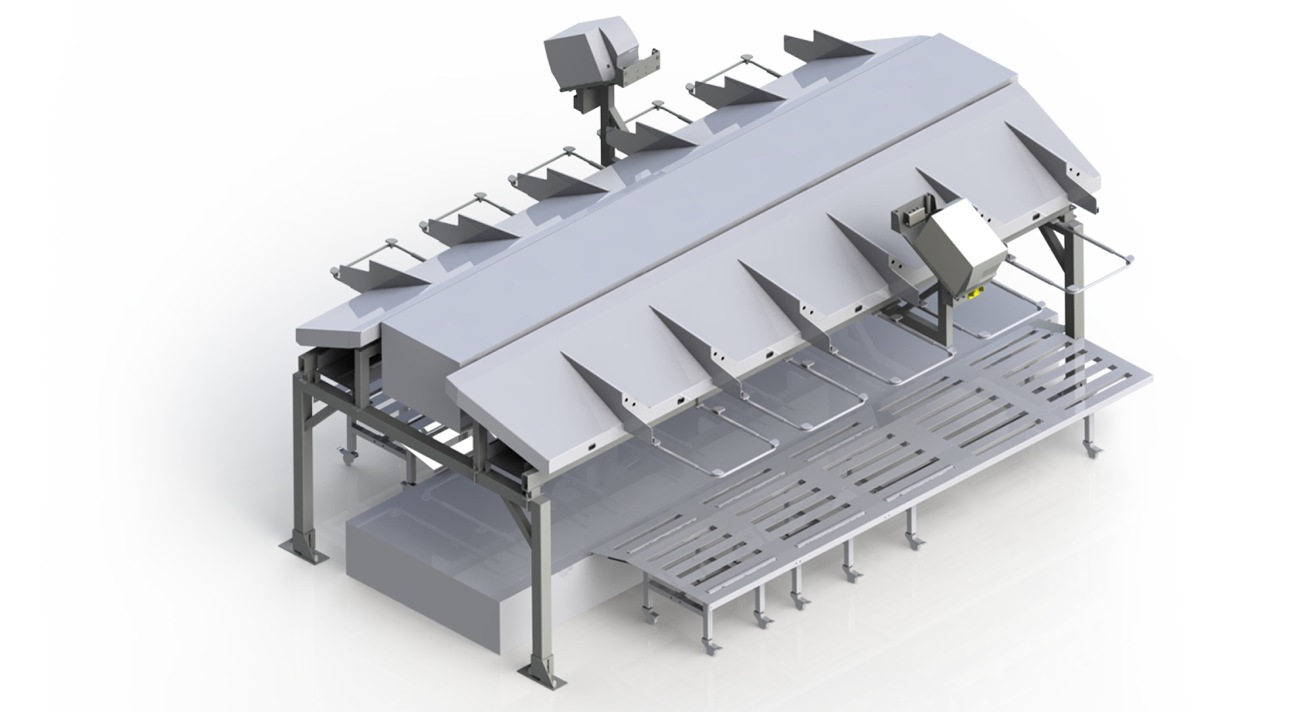

The grid chute is a small piece sorting chute matched with the single-layer cross-belt sorter

Learn More

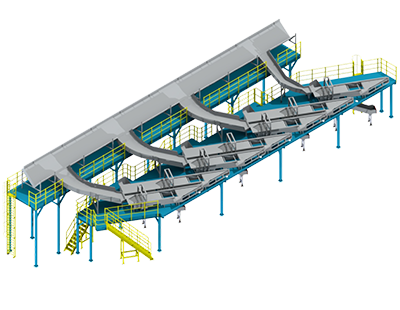

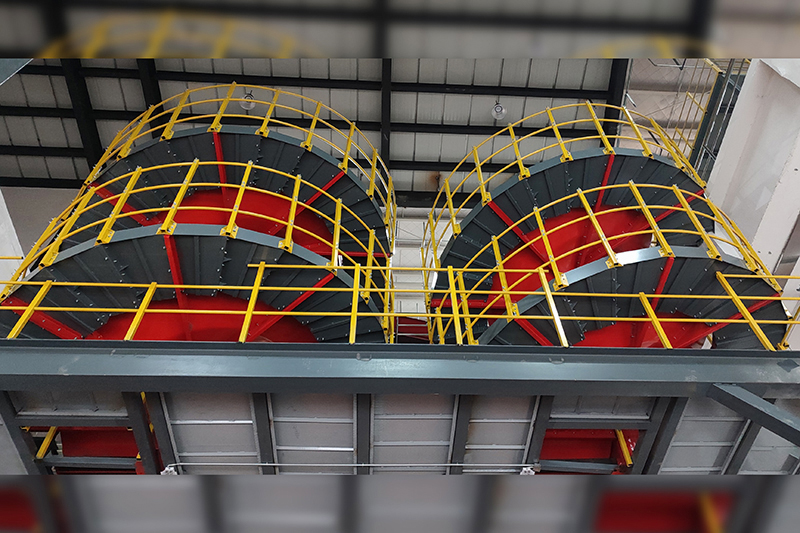

Can be customized according to customer needs, all kinds of light steel, heavy steel and attic storage steel platform, fully assembled structure

Learn More

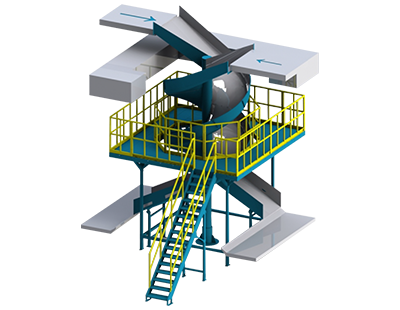

Spiral chute is mainly used for vertical unpowered conveying of material system

Learn More

Jiangsu Yeshen Logistics Equipment Co., Ltd., formerly known as Changshu Yeshen Metal Products Factory, was founded in 2003 and is located in Shanghu Town, Changshu, a beautiful water town in the south of the Yangtze River. It is a high-tech enterprise integrating design, R&D and production with more than 20 years of production experience, providing customers with one-stop logistics system solutions. So far, it has established an international modern production base covering an area of about 25,000 square meters (the third phase of planning), with more than 150 R&D equipment, production equipment, and testing equipment. The company has a team of more than 200 people, including a technology research and development team, who escort the development of the company.

The company mainly produces logistics sorting equipment, steel pallets and other products, and can design and customize various non-standard products for customers. The products have passed the ISO9001:2008 international quality management system certification and international standard certification. Over the years, Yeshen products have been exported to more than 30 countries and regions such as Southeast Asia, Europe, and North America while meeting the needs of domestic customers. It has established strategic partnerships with many group companies.

Since the establishment of the company, it has always been people-oriented and the principle of integrity first has developed rapidly. From pre-sales communication to centralized research and development, design, production, testing, distribution and installation, it adopts one-stop service throughout the process. All employees in this company sincerely thank you for your support and love.

Since 2003

Modern Production Base

Exported to Countries All Over The World

Customer Service

Products

Diamond Chute

Diamond Chute

Small NC Spiral Chute

Three Entrance Spiral Chute

Belt Conveyor Spiral Chute

Maintenance Platform Spiral Chute

Parcel Sorter Spiral Chute

Package Sorting Spiral Chute

Equipment Steel Platform

Equipment Steel Platform

Equipment Steel Platform

Automatic Matrix Sorting Chute

Clothing Sorting Grid Chute

Double-layer Grid Chute

Small Double-layer Grid Chute

Small Single-layer Grid Chute

Multi-layer Small Pieces Sorting Grid Chute

Small NC Spiral Chute

Three Entrance Spiral Chute

Belt Conveyor Spiral Chute

Maintenance Platform Spiral Chute

Spiral Chute

Fulai Wheel Turning Chute

ADVANTAGE

富有朝氣的研發(fā)團(tuán)隊(duì)

設(shè)計(jì)中心

智能化的生產(chǎn)基地

質(zhì)量管理保障

Rich technical experience, Won a number of technical invention patents

Every set of logistics sorting equipment in the design center is designed and manufactured

High-quality products lie in the pursuit of details

Strictly implement the ISO9001 quality control management system

partner

Yeshen's products meet the needs of domestic customers while

It is also exported to more than 30 countries and regions such as Southeast Asia, Europe, and North America.

Established strategic partnerships with many group companies

Contact Us >>NEWS

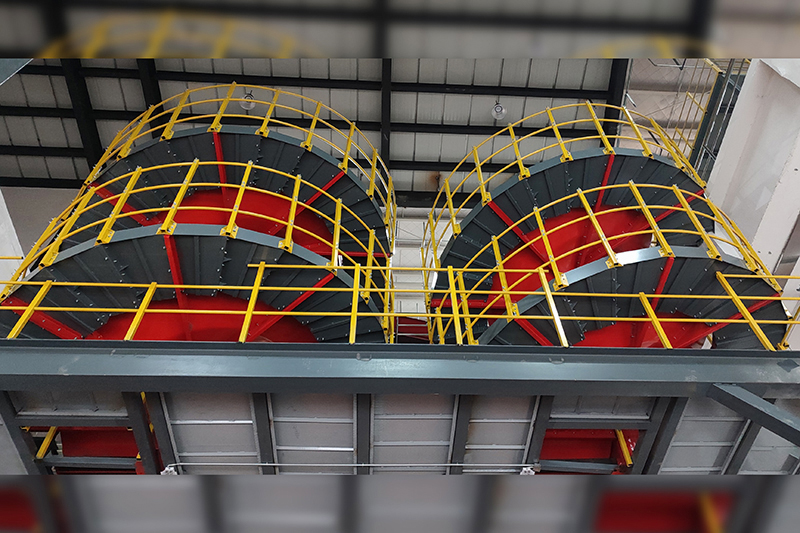

The multi-layer small-item sorting chute is a core component of automated logistics sorting systems. It is primarily used for the rapid sorting and temporary storage of small parcels (such as documents, packages, and parts) in industries like express delivery, e-commerce, and books. Compared to traditional single-layer sorting equipment, it features a multi-layer three-dimensional layout and a gra

The drum straight groove is a core auxiliary component in the conveying and sorting system, consisting of parallel arranged drums and straight groove bodies. It relies on the rolling and drag reducing characteristics of the drums to achieve directional conveying of materials along a straight line. Its core function revolves around four dimensions: unpowered conveying, efficient diversion, bufferin

The core function of a straight chute is to rely on gravity to achieve linear directional conveying, diversion, or buffering of materials/items. It has a simple structure but is adaptable to multiple scenarios, with a focus on "efficient diversion, stable transmission, and low-cost adaptation". It is specifically reflected in six core dimensions and adapts to the needs of different industries:

As a commonly used equipment in logistics sorting and other scenarios, diamond chutes have significant advantages in cargo protection, conveying efficiency, installation and use due to their special structure and excellent materials. The following is a detailed introduction:

The drum straight chute is a core equipment in logistics and warehousing that relies on gravity to achieve non powered transportation of goods. It has the characteristics of simple structure, low maintenance cost, and stable transportation efficiency. It is widely used in warehousing sorting, loading and unloading, cargo diversion and other scenarios. The specific applications are as follows:

The four layer grid chute for small items is a core equipment in e-commerce warehousing that adapts to the efficient flow of small goods. With the spatial intensity of the four layer three-dimensional structure and the classification and sorting ability of multiple grid ports, it is mainly used in core links such as sorting and diversion of small goods, storage and temporary storage, and order ful

The multi-layer small-item sorting chute is a core component of automated logistics sorting systems. It is primarily used for the rapid sorting and temporary storage of small parcels (such as documents, packages, and parts) in industries like express delivery, e-commerce, and books. Compared to traditional single-layer sorting equipment, it features a multi-layer three-dimensional layout and a gra

The drum straight groove is a core auxiliary component in the conveying and sorting system, consisting of parallel arranged drums and straight groove bodies. It relies on the rolling and drag reducing characteristics of the drums to achieve directional conveying of materials along a straight line. Its core function revolves around four dimensions: unpowered conveying, efficient diversion, bufferin

The core function of a straight chute is to rely on gravity to achieve linear directional conveying, diversion, or buffering of materials/items. It has a simple structure but is adaptable to multiple scenarios, with a focus on "efficient diversion, stable transmission, and low-cost adaptation". It is specifically reflected in six core dimensions and adapts to the needs of different industries:

As a commonly used equipment in logistics sorting and other scenarios, diamond chutes have significant advantages in cargo protection, conveying efficiency, installation and use due to their special structure and excellent materials. The following is a detailed introduction:

The drum straight chute is a core equipment in logistics and warehousing that relies on gravity to achieve non powered transportation of goods. It has the characteristics of simple structure, low maintenance cost, and stable transportation efficiency. It is widely used in warehousing sorting, loading and unloading, cargo diversion and other scenarios. The specific applications are as follows:

The four layer grid chute for small items is a core equipment in e-commerce warehousing that adapts to the efficient flow of small goods. With the spatial intensity of the four layer three-dimensional structure and the classification and sorting ability of multiple grid ports, it is mainly used in core links such as sorting and diversion of small goods, storage and temporary storage, and order ful

WeChat number:業(yè)神物流設(shè)備

WeChat number:業(yè)神物流設(shè)備